Did you know that workplace explosions account for thousands of injuries each year?

In industries like oil and gas, mining, and aviation, even a single spark from the wrong equipment can lead to disaster. But many of these incidents are preventable, with the right safety measures and ATEX-certified lighting solutions.

1. Explosions and Fires

The Risk: Industries dealing with flammable gases, vapours, liquids, or combustible dusts are at constant risk of explosions. Even a small spark from an electrical source can trigger a catastrophic event, particularly in classified hazardous zones like Zone 0, Zone 1, and Zone 2 for gases or Zone 20, Zone 21, and Zone 22 for dust.

How to Prevent It:

- Use ATEX-certified lighting that is intrinsically safe and explosion-proof, ensuring no sparks or excessive heat are generated.

- Ensure proper ventilation in areas where flammable substances are present.

- Conduct regular maintenance checks on electrical and lighting equipment to prevent failures.

|

Featured product: Sigma Pro ATEX Head Torch Why? This intrinsically safe ATEX Zone 0 head torch eliminates the risk of sparks in hazardous areas, making it perfect for explosive environments like oil, gas, and mining industries. |

2. Slips, Trips, and Falls

The Risk: Poor lighting in hazardous areas increases the likelihood of slips, trips, and falls, especially in industrial zones where oil, gas, or liquids can create slippery surfaces.

How to Prevent It:

- Install high-lumen ATEX lighting to improve visibility in dimly lit areas, ensuring workers can navigate safely.

- Use portable ATEX torches and floodlights for temporary or emergency lighting solutions.

- Keep workspaces clean and clear of obstacles, with proper flooring to reduce slip risks.

|

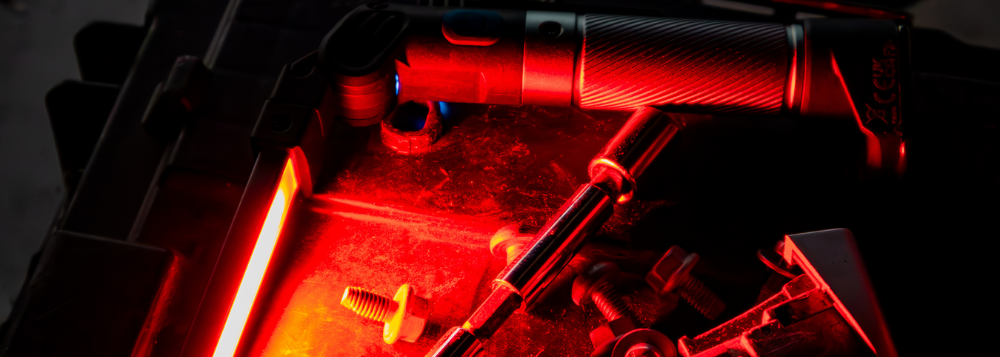

Featured product: Sigma RA Right Angle Flashlight Why? Its high-lumen output enhances visibility, helping workers safely navigate hazardous zones while reducing the risk of accidents. |

3. Electrical Hazards

The Risk: Electrical equipment in hazardous zones must be specially designed to prevent ignitions caused by sparks or overheating.

How to Prevent It:

- Use intrinsically safe ATEX-certified lighting that meets EU Directives for explosive atmospheres.

- Train employees to identify faulty wiring and report potential electrical hazards immediately.

- Regularly inspect lighting and electrical installations for wear and tear.

|

Featured product: Sigma 4AA ATEX Flashlight Why? Built to ATEX Zone 0 standards, this hand torch is safe to use in environments where electrical sparks could pose serious risks. |

4. Poor Visibility in Confined or Remote Spaces

The Risk: Confined spaces such as tanks, tunnels, and underground facilities often have limited airflow and poor lighting, increasing accident risks.

How to Prevent It:

- Equip workers with portable ATEX head torches and hand lamps to ensure visibility in confined spaces.

- Implement safety procedures such as buddy systems and proper ventilation checks before entry.

- Use high-power ATEX floodlights for sustained illumination in large work areas.

|

Featured product: Sigma RSL1000 ATEX Searchlight Why? This high-powered hand lamp provides strong illumination in confined spaces such as tanks, tunnels, and underground facilities. |

5. Equipment Malfunctions and Failures

The Risk: Defective or non-compliant equipment can result in dangerous failures, putting workers at risk of injury, fire, or explosions.

How to Prevent It:

- Use only ATEX-certified lighting and equipment, specifically designed for hazardous zones.

- Conduct routine maintenance and testing to ensure compliance with safety regulations.

- Train employees to recognize warning signs of equipment failure and respond appropriately.

|

Featured product: Titan R Rechargeable ATEX Floodlight Why? With its durable, explosion-proof design and high-lumen output, this rechargeable floodlight ensures reliable lighting in high-risk industrial environments. |

The Role of NightSearcher’s ATEX Lighting Solutions

At NightSearcher, we offer a comprehensive range of ATEX-certified portable lighting solutions, ensuring the highest level of safety in hazardous environments:

- Intrinsically Safe Head Torches and Hand Lamps: Designed for hands-free operation and personal safety in explosive zones.

- ATEX Floodlights and Work Lights: Providing powerful illumination for large hazardous areas.

- IP67 Rated, Durable, and Explosion-Proof Designs: Ensuring reliability in extreme industrial conditions.

Ensure your workplace is equipped with the safest lighting solutions available. Explore NightSearcher’s ATEX range today and create a safer working environment for all.

Laisser un commentaire

Ce site est protégé par hCaptcha, et la Politique de confidentialité et les Conditions de service de hCaptcha s’appliquent.